Have you ever wondered how casting dumbbells are made? Here we introduce how to make a dumbbell and the reason why you should choose iron casting dumbbells for strength and muscle exercise. Scroll down and explore with us.

Dumbbells are the weight training equipment which popularly used in the gym as well as at-home exercise. As you often see, they come in a range of types, designs, materials, and weights that definitely confused you in the beginning.

Check list of dumbbells for all workout benefits

Among the various selection, the fixed weight cast iron dumbbell might be more popular than others. They are because cast iron dumbbell not only shows great performance in strength, endurance, and muscle exercise but also works pretty durable over time. You would only pay for one time, but your casting dumbbells last for a lifetime.

The dumbbell seems so similar to us, but surely most of you are nearly to know nothing about how to make iron casting dumbbells.

Broaden your knowledge, today we introduce the dumbbell casting process in our cast iron foundry.

From the designing step, molding, pouring, machining to the coating process, you will catch the idea of how we make excellent pieces of dumbbell for our clients.

How to make a dumbbell?

Briefly, the cast iron dumbbell is made by the casting process. The molten cast iron is poured into the mold cavity after the sand molding. Wait for cooling, the casting will be collected. Detailed particular steps are fully explained below.

1. Designing Dumbbell

As you see, the casting dumbbell comes in various designs. They can be listed as round, hex, globe, square, etc. just for a while. That still has not counted the detail styles in each round, hex, or globe type.

Normally, each dumbbell features its brand characteristics such as logo, brand name, unique sign, etc.

Take the example of Golden Cast Iron, they sell the only one type of casting dumbbell that casts “Made in USA” impressively as their brand’s declaration. York Barbell also shapes its name of “York” to the dumbbell surface finish. Or there is a fitness brand that comes with an “S” sign as an acronym of Strength, Super, and Star.

Yes, the dumbbell design comes in a range of options and weight and the designing department always has to work hard to turn the customer idea into perfect drawings.

The dumbbell design step can be divide into type cases: the OEM or ODM service.

If the order is OEM, the customer sends the 2D/3D drawing to the foundry. In this case, the designer can skip the product design step and move on to the pattern design process. It will save time and effort.

For the ODM casting dumbbells order, the foundry will be in charge of product design as well. The customer speaks their requirements and the designer will export 2D and 3D drawings.

Request for your own dumbbell design here!

2. Making Dumbbell Pattern

The next process of how to make a dumbbell is pattern making.

It is not exaggerated to say that the pattern is the soul of cast iron dumbbell as well as all iron casting products.

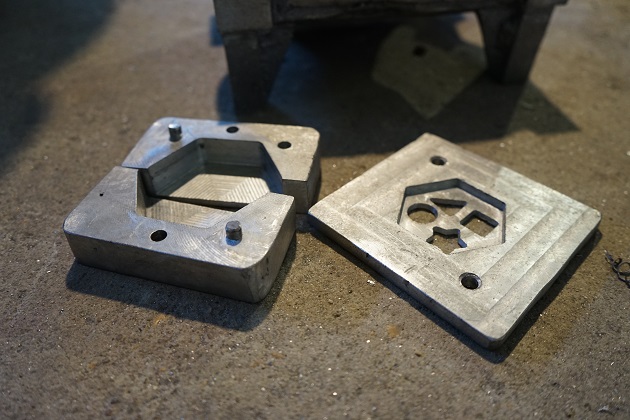

The pattern is a replica of the final casting dumbbell using to place into the sand flask to create the mold cavity that allows pouring the metal. Only if the pattern is carefully designed, the dumbbell casting can process well.

Once the 3D drawing is confirmed, the pattern design will be passed to the foundry to start making the pattern. It is often made of aluminum material and processed by the CNC machine. Optionally, depending on specific requirements and the quality of the pattern, it will be passed to other machining steps such as milling, welding, lathe, drilling, etc.

The casting dumbbells pattern is often made by creating different parts of the dumbbell and then assembled them together while making a mold cavity. This method allows adding a logo and sign as a customer’s desire.

3. Molding sand

Green sand casting is the molding process mostly used for casting cast iron dumbbell.

This process used green sand (a kind of wet-content sand that bonding naturally) to create the mold. Simply explained, the sand is loading into a flask (either manual or semi-automatic); then the pattern is press into the sand flask; when pattern removal, a mold cavity is created and ready for the pouring step.

4. Casting dumbbells

The raw cast iron input goes through the Spectromax Machine to analyze the material component.

Once the raw cast iron qualifies, it is passed to the furnace and melted. The melting point of cast iron is something at 1260oC.

The molten cast iron then is poured into the sand mold cavity.

A semi-automatic line is usually applied in this step in foundries. After the pouring, it requires to wait for 6 to 8 hours for cooling. The roughcasting is collected and to the sand-blasting to clean the remaining sand. This is the roughcasting step of how to make a dumbbell. All the processes are tight control by our QC process to ensure high quality, minimize rejection and satisfy our clients.

Check out quality control process to ensure high quality products

4. Machining dumbbells

The last process of how to make a dumbbell is the machining step.

The dumbbell roughcasting after collected is passed to the machining step. Here, the worker based on the requirement to have further treatments such as milling, polishing, smoothing, drilling, welding, coating, etc. to complete the casting dumbbell product.

The inspection is tightly controlled in every manufacturing step to guarantee the cast iron dumbbell quality.

The qualified cast iron dumbbells have to meet these requirements including no casting defect such as cracks, pinholes; proper weight; good coating; drop testing pass.

Read more How kettlebells are made?

Are cast iron dumbbells good?

The answer is definitely yes. Among dumbbell material, cast iron dumbbells are one of the most preferable weights due to their fabulous benefits.

- Firstly, let’s talk about the cast iron dumbbell property. Cast iron itself has a density more than steel, plastic, concrete, vinyl. In comparison, the cast iron dumbbell will save volume and dimension better than other materials. Take an example of 5 pounds cast iron dumbbell that will be smaller than the 5-pound plastic or concrete weight by dimension but keep the same weight. Hence, it will save space to store and also portable to other places.

- Secondly, the cast iron dumbbell provides the proper weight that supports the workout better. You can find a range of cast iron weight selections from light to heavy level for different workouts. Plus, the cast iron dumbbell also gives a firm grip during the exercises.

- Thirdly, the cast iron dumbbell is pretty cost-effectiveness. You only pay to buy cast iron dumbbell once, and it will last a lifetime.

How to choose dumbbell for your exercise?

Where to place a dumbbell order?

If you are looking for a manufacturer and wholesaler of cast iron dumbbells for the USA and EU market, we confidently introduce ourselves as one of the reliable casting dumbbells manufacturers in the world for over a decade.

We are specialized in supplying casting products to the most demanding market including North America and Europe.

For the dumbbell category, our casting dumbbells ability allows producing different types of cast-iron weights. Cast iron fixed weight, adjustable dumbbell with cast iron plates, hex weight, or round shape, we are able to meet all the requests.

With the full-equipment investment, our foundry can take charge of all procedures without asking for third parties’ help. At VIC foundry, all the manufacturing processes are strictly controlled and supervised from the input material to casting, machining, and packing procedure.

An order with VIC will surely satisfy all of your requests.

Browse our website to check out production ability. Also, contact us to a place a question for casting dumbbells product.

Why you should buy kettlebell for your home gym?

Kettlebell Vs Dumbbell Vs Barbell: Which one you should buy?