The growing popularity of at-home exercise has prompted gym fans to purchase high-quality kettlebell sets to make their training explosive. Have you also decided to incorporate some kettlebells into your workout? Check out another episode of our kettlebell buying guide to find yourself a perfect fit.

You might wonder why kettlebells are so popular.

Kettlebells are already well-known in CrossFit, but recently, its merits as an isolated sport in strengthening the limbs, back, shoulders, and core are getting even more attention.

Thanks to their incredible muscle kick paired with high-intensity cardio that makes us sweat like mad, no wonder why kettlebells are invading the weight racks at the gym and the home of many fitness lovers.

Kettlebells have an “easy-to-understand” structure. Funny enough, many people find it difficult to distinguish which is desirable and which is not.

If you’re just a regular trainer, there aren’t many aspects of a high-quality kettlebell to consider. Simple as it looks – a cannonball with a handle attached, all you need to focus mainly lie on the quality of the construction and the coating finish.

Last time we’ve covered some of the most desirable coatings and warned readers what to avoid. This time, the topic is on everything related to the construction of a kettlebell and how important it is.

Let’s get into it, shall we?

Look no further than the kettlebell to enhance your workout, whether it’s cardio or strength training.

This functional piece of equipment provides a total-body workout by working both large and small muscle groups.

Kettlebell exercises might take a lot of technique and coordination, but they will help you develop endurance, stamina, and power if performed correctly.

How important is a well-built kettlebell?

The kettlebell, which can be traced back to Russian roots, first appeared in documents around 300 years ago and is authentically recognized to be made of cast iron and steel.

Despite being a simple ball with a handle attached to the top, kettlebells aren’t easy to produce, that there are multiple steps to carry on.

You want your kettlebell to be not only durable but also feel comfortable in your hands, even during the most intense workouts?

The proper kettlebell construction will help you with that and allow you to perform every movement seamlessly.

Coming in various shapes and sizes, material analysis and testing are needed before getting into hours or even days of the production process.

Check out the best kettlebell for your body workout!

So what is a good kettlebell construction?

You’re thinking about getting a kettlebell? Then don’t settle for anything less than this.

The conventional and still, the best kettlebell design is constructed of a single solid piece of metal casting that is not covered or coated in plastic, with a handle of the standard diameter for your hands and a flat, but not too wide, base.

The length of the horns, which are the handle stems that extend from the bell, is also essential.

Not only does this give you space to place your hands, which could be 1 or 2 depends on the workout, but it also allows you to adjust the relative location of the mass center.

Therefore, determining the ease and level of comfort of a kettlebell product.

In a nutshell, every angle of a well-made kettlebell, from the handle width, the location of the mass center, to the shape of the bell, etc., must be carefully checked.

But for now, let’s focus on the construction!

Kettlebell Construction Methods

Regardless of the material, how a kettlebell is made is equally important since it directly contributes to the overall performance, durability, and appearance of the final product.

Kettlebells differ from other forms of fitness equipment, such as dumbbells and barbells, in that they comprise two parts: a single weight and typical loop handle.

The body of the bell is typically spherical, and they come with a range of differing weights.

Though kettlebells can be made in multiple ways, single casting and two-piece assembly are the most common.

What is that mean?

A single casting kettlebell is constructed from a single metal mold, while a two-piece kettlebell has the handle welded to the “bell.”

With that being said, a single piece of metal is definitely much stronger and secure than one that has been welded together.

If the kettlebell’s handle is welded on, it is much more likely to break if dropped. You don’t want the weighted ball to come flying off the handle during a swing, do you? That flying cannonball will destroy whatever it hits, no matter how light it is for a kettlebell.

If you want to know whether a kettlebell is made of one solid metal piece or not, look for words like “Single Cast” or “Single Piece Casting” in the description. You can also look at the photos closely if you shop online or check the kettlebell in person to see if there is any welding around the junction of the handles and the ball of weight.

Unfortunately, as many designs developed along the way, various manufacturers have made many compromises to reduce expenses or hide their design inadequacies. And what they use to make kettlebells is worth noticing.

Read more: How single cast iron kettlebell differs from cement filled weight?

Kettlebell Construction Materials

If you’re thinking of getting into kettlebell training, you probably have some questions about its material and find so overwhelmed with what’s available in the market.

Don’t panic; we are here to help!

Along with a bunch of selections in terms of designs, materials used for kettlebell making also vary. When you go through the category of kettlebells, you will notice many different kinds of kettlebells, but what actually makes a difference is mostly the material.

As you scroll through the kettlebell list, you’ll find that there are multiple different variations of this odd-shaped bell, such as “cast iron kettlebell,” “steel kettlebell,” “vinyl kettlebell,” “PVC kettlebell,” and so on.

But will such different materials have an impact on the user experience?

The Best Kettlebell Materials

Do you have a sense of what a high-quality kettlebell material would be like?

Want to make a profitable investment in free-weight sets?

Aim at ones that are made of durable and robust metal. In this case, the two most influential candidates are Cast Iron and Steel.

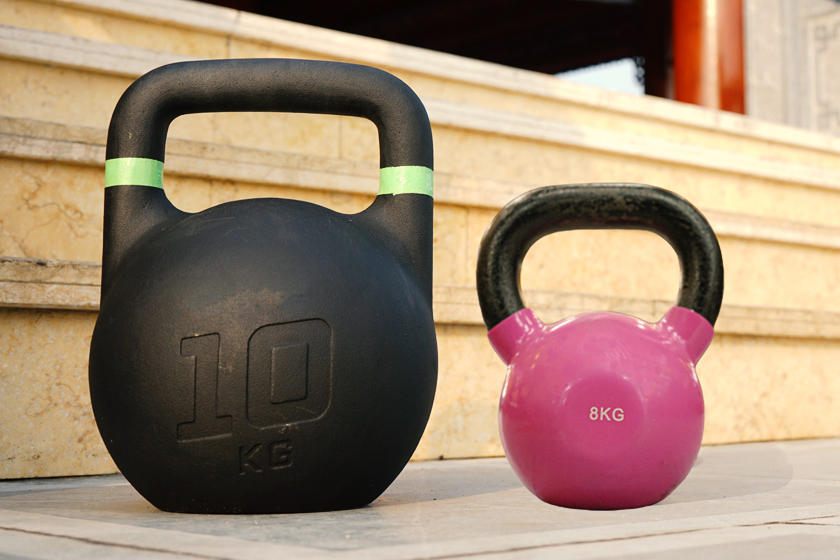

While cast iron is the soul of the kettlebell line, and that’s chiefly what you’ll find in the gyms or fitness club, steel is what to use in the manufacture of “competition” or “sport” kettlebells.

Although many different types of materials and metals can be cast, iron and steel casting are the most common due to their mechanical properties, which allow for widespread use, reliability, and durability.

Cast Iron kettlebells

Single cast kettlebells made of cast iron with matte black powder coat finish are seen in the industry as the standard.

It’s not easy to find a comparable fitness kettlebell that is affordable and offers such excellent value for money as what’s made of cast iron.

Why is this material superior?

- Cost-effective

Cast iron save a lot of money in the long run.

For a long time coming, cast iron will take little to no maintenance, so using it will save money by reducing the need for replacement.

Besides, cast iron goods may be incorporated into existing constructions, thereby minimizing the replacement costs.

2. Amazing Strength and Durability

As one of the most widely used materials in a variety of applications, cast iron has high strength at reduced costs. And that’s what makes it a workable material in a range of industries, including fitness production.

Furthermore, the cast iron will not crack or dent. It withstands amazingly the test of time due to the incredible durability and strength, and it does not succumb to problems easily. Also, the durable nature of this material helps to prevent deformation.

So that’s the secret to how cast iron kettlebells can maintain their shape after years of rigorous workouts.

3. Castability

Cast iron is used in an array of industries because of the ease of its castability.

As its malleability is more flexible than many other metals, the cast iron can be molded easily into various shapes and sizes based on diverse industrial needs.

Plus, it’s also a viable fitness manufacturing material because of the low cost of production and the limited use of tools.

4. Outstanding Machinability

Cast iron can be easily machined into final products. This is an excellent feature for those who have to work with this material.

Since some properties like hardness, tensile strength, and microstructure can alter its machinability, manufacturers can freely customize their own cast-iron mixture by adding or changing the components.

Cast iron’s machinability also aids in cutting and finishing it at a low cost and in a short amount of time.

Steel Kettlebells

Stainless steel is used in a number of ways. Its resistance to corrosion and stains, coupled with low maintenance, make it an ideal option for many applications: architecture, monuments, sculptures, vehicles, aircraft, fitness equipment, and so on.

How awesome is it? Let find out!

- Strength and Durability

One of the main reasons stainless steel is most sought after is its strength, which it retains at both extremes of temperature.

Steel kettlebells are a little more durable than their cast iron counterparts, and due to the density of steel being even more malleable, they can be made all in one size regardless of weight changes.

Stainless steel is a very tough metal that even lightweight stainless steel will not buckle under extreme pressure, making it one of the most durable metals available. It can endure a significant amount of weight, hot and cold temperatures, and extreme weather conditions.

2. Aesthetics

The appearance of stainless steel is one of the main reasons why people prefer it.

Stainless steel has a modern and appealing appearance due to its shiny, easily maintained surface.

Not only being stylish, with both traditional and contemporary elements, the metal is also extremely functional.

3. Corrosion Resistance

This metal stands strong against corrosion, rust, water stains, and more, making it suitable for applications involving temperature and pressure extremes.

Chrome is applied to stainless steel during fabrication, which reacts with oxygen in the air to form a film over the metal. When this film is damaged, it can quickly restore itself, allowing the metal to endure corrosion and rust.

Other elements (such as nickel, titanium, and molybdenum) can also be added to stainless steel to improve its corrosion resistance even more.

Are they the same?

Steel kettlebells

Cast iron kettlebells

Many would assume that steel and cast iron features may sound very similar; however, each material has its own set of advantages and disadvantages.

The carbon content of the materials is the most significant distinction between cast iron and steel. Cast iron usually has a more than 2% carbon content, while steel remains at around 0.1-0.5%.

What does this imply in terms of casting differences?

The more carbon in the iron, the more malleable it becomes. Therefore, cast iron is simpler to cast than steel because it melts more readily and does not shrink as much. This means that filling complex voids inside molds requires less molten content, making cast iron suitable for more complicated structures. This is why cast iron is often used for ornately designed projects such as fencing and street furniture.

However, though cast iron is generally more accessible to machines, it breaks away more easily and uniformly than steel.

Stainless steel, on the other hand, has a significant advantage over cast iron in terms of impact resistance. Its remarkable ability to withstand high-stress forces allows the metal to withstand heavy impacts without deforming, cracking, or even bending.

Steel is also ideal for mechanical and structural applications, and because of its load-bearing capabilities, it is the most widely used metal on the planet.

Cast iron is generally less expensive than cast steel because the cost of material, energy, and labor are all lower. Purchasing raw steel is more expensive, and the casting process requires more time and resources.

What to say “NO”

Unfortunately, in the market these days, you will find big variations in the kettlebell construction quality.

Except for the two materials listed above, you should think twice about buying kettlebells made of cement, plastic, sand, or anything else.

Kettlebells may be partially or entirely coated in materials such as rubber or polyurethane for a more appealing look, and they are often marketed as providing “a protection” for your floor if you accidentally dropped it during the exercise.

These seem to be great cost-effective options, better than cast iron, but apart from the vibrant color, these materials can never match solid metals.

In fact, there have been dozens of consumer complaints about how poor quality these cheap kettlebells are, and experts clearly do not recommend them.

Read more: Is it worthy buying cheap kettlebells?

Vinyl or PVC kettlebells can be understood as a free-weight type with a 90% metal or cement structure, and the remaining 10% is vinyl or PVC coating.

Despite the fact that many manufacturers market their vinyl kettlebells as “protective covering material,” it is primarily used for aesthetic purposes. Furthermore, when trainers sweat their palms, this synthetic resin and plastic layer is just going to make a kettlebell more slippery and hard to handle, which can be extremely dangerous during intense lifting sets.

Though this coating aids in making the surface of the kettlebell to be less rigid, it is debatable if it can really protect your floors, as depicted in the advertisement.

You want to know why?

It’s because that a kettlebell, regardless of material, is still a substantial weight that can totally damage your floor if heavy enough.

There has been a lot of controversy about whether to buy weights constructed from cheap materials all over the fitness network media. Yet, the majority of the fitness community agrees that cement-filled, concrete-filled, vinyl-coated, or sand alternatives, etc., can be used as something heavy to lift, not for serious kettlebell training.

Additionally, they believe that those are typically performed poorly due to the filling, grip, and weight distribution.

Is it worth investing in cement or some other kettlebell that isn’t made of the two traditional materials?

The answer is no. You will regret buying those kettlebells in no time.

You might find yourself pleasant to the eye bell at a low price, but in return, the bell easy to break, the grip is awkward, the weight can be messed up, the weight distribution is uneven, etc.?

Will it serve long-term use?

Definitely not!

Cement kettlebells have received countless criticism for chipping easily, and even though vinyl kettlebells can be made of party cast iron, there’s no way of knowing the inner metal is sufficiently filled or defect-free. And you can not check that because they are all covered up.

Spending money on those uncertain items would be quite a risk because what you need in a kettlebell is the exact weight, durability, and a comfortable grip, not any appearance factors.

Conclusion

It’s no coincidence that cast iron or steel kettlebells are so popular and recommended; there must be a reason.

A high-quality material not only ensures the longevity of your kettlebell but also makes your time, money, and training worthwhile, so make sure you do your research thoroughly before coming up with any purchase and wish you a great kettlebell training.