How to choose proper types of aluminum for different casting applications? Here we specify aluminum classifications, their properties, and a guide to select aluminum for a range of casting uses.

Aluminum is one of the most abundant elements on the Earth and widely used in many different industrial and non-industrial applications because of its good properties and versatility. From shipbuilding, automotive, aviation, decorative parts, outdoor furniture to kitchen accessories, we all see aluminum applications.

Aluminum varies in many types. Depending on the specific uses, there will be suitable types of aluminum with their particular properties. With different properties and chemical composition, each type of aluminum will behave differently in the process.

Therefore, it is very important to classify aluminum to understand the properties of each type to help the manufacturer choose the proper material for casting that meets the desired quality and customer’s requirement.

Grab this demand of knowledge, we open an article to discuss how to classify basic and common different types of aluminum and aluminum alloys go along with their characteristic properties and main applications.

Stay with us to dig out the answer!

- Aluminum

- Aluminum alloy

- Aluminum alloy definition

- Characteristics of Alloying Elements

- Designation System of Wrought aluminum alloy and Cast aluminum alloy

- Designation System of Heat treatable and Non-Heat treatable aluminum alloy groups

- Things to Consider when Choose Types of Aluminum for Casting Applications

- Specify Types of Aluminum for Different Casting Applications

- Rotor Casting Parts

- Piston Casting Parts

- Premium-Quality Casting Applications

- Standard General-Purpose Casting Parts

- Conclusion

Aluminum

Aluminum is considered as one of three most common elements on Earth, just place behind Oxygen and Sillic.

The chemical symbol of Aluminum is Al; Mass atom is 27 with atomic number of 13.

Although aluminum is quite common in nature, it is rarely found in its pure form. Instead, aluminum is often found in substances such as clay, bauxite, etc. Statistically, aluminum is found in about 270 different types of minerals.

General Physical Properties of Aluminum

- High aesthetic: Aluminum has nice silver whiter and a good appearance when processed.

- It is soft (second only to gold); light in weight (its density of aluminum is only about one-third of iron or copper).

- Malleable (places in the sixth)

- Good electrical and thermal conductivity.

- Good corrosion resistance and durability due to the Al2O3 protective oxide layer

- It is also non-magnetic and does not burn when exposed to air under normal conditions.

- Low melting point (660° C) that can facilitate the melting process

- It does not have high cast-ability due to large shrinkage (up to 6%).

General Mechanical Properties of Aluminum

Aluminum has low mechanical properties (σb = 6Kg / mm2, HB = 25, δ = 40%) so it is easy to deform, low cutting machinability.

The yield strength of pure aluminum is about 7–11 MPa, while aluminum alloy has a yield strength ranging from 200 MPa to 600 MPa.

Aluminum alloy

Aluminum alloy definition

When fabricating aluminum, it is common for manufacturers to add alloys (such as Cu, Mn, Mg, Si, Sn, Zn) to improve the properties of aluminum.

Depending on each purpose of the application, they are combined in different to produce an aluminum alloy with the desired properties.

To sum up, aluminum alloy is the combination of the aluminum element with alloying elements to increase workability, corrosion resistance, electrical conductivity, density, strength, etc. comparing with the pure aluminum element.

Characteristics of Alloying Elements

The basic alloying elements used to improve the properties of aluminum alloys include: Cu, Si, Mn, Mg and Zn.

Here are the properties of each alloy element when adding to the aluminum:

| Alloy element | Properties |

| Copper (Cu) | Improves durability and formability |

| Silicon (Si) | Reduces melting temperature, increases flow dilution, and improves casting properties |

| Manganese (Mn) | Increases strength and toughness |

| Magnesium (Mg) | Improved durability, and resistance to corrosion |

| Mg / Si | Increases strength, formability and tensile properties |

| Zinc (Zn) | When combined with Mg and Cu, it improves durability |

Designation System of Wrought aluminum alloy and Cast aluminum alloy

Separately, based on the method of fabrication and usage, we divide aluminum alloy into two main groups is Wrought aluminum alloy and cast aluminum alloy.

Wrought aluminum alloy

As mention above, the alloy elements are added to aluminum in a certain proportion. With wrought aluminum alloys, the amount of alloy elements is less than 4% of the total mass.

Wrought aluminum alloy is made by melting aluminum ingots with alloy elements, then cast into large plates before rolling, forging, or pulling into different object shapes. Based on the fabrication, wrought aluminum alloy comes in a variety of shapes, including sheet, plate, foil, wire or rod, etc.

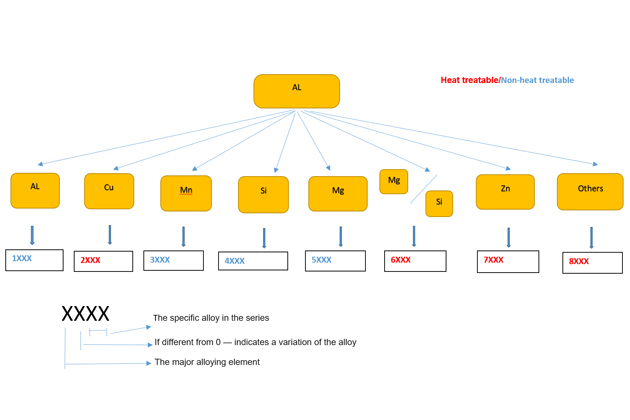

Depending on the alloying element composition, wrought aluminum alloy can be grouped into 7 main groups and 1 special group (group 8) as shown below.

In which, groups 2, 6, 7, 8 are heat-treatable groups to improve some mechanical properties, while groups 1, 3, 4, 5 belong to non-heat-treatable group.

For Example:

Aluminum alloy 5083 means belonging to group 5, Aluminum-Magnesium (Al / Mg) alloy; the original version (0); and the 83 identifies it in the 5xxx series. Aluminum 5183 is the first variant version of aluminum 5083.

All wrought aluminum alloy series follow this explanation. There is only one exception is 1XXX series of aluminum alloys (pure aluminum). In which, the last third and fourth digits indicate the minimum aluminum percentage above 99%.

For example, aluminum alloy 1350 has 99.50% minimize pure aluminum.

Table of Properties of Wrought aluminum alloy series

| Alloy series | Corrosion Resistance | Strength | Machining | Weldability | Formability/ Workability |

| 1XXX | ☑ | ☑ | |||

| 2XXX | ☑ | ||||

| 3XXX | ☑ | ☑ | ☑ | ||

| 4XXX | ☑ | ||||

| 5XXX | ☑ | ☑ | ☑ | ||

| 6XXX | ☑ | ☑ | ☑ | ☑ | ☑ |

| 7XXX | ☑ | ||||

| 8XXX (others) |

Cast aluminum alloy

Having a larger amount compared to wrought aluminum alloys, cast aluminum alloys contain more than 22% of alloy elements.

Cast aluminum alloys are made by smelting bauxite (bauxite) ores in a furnace. Then the pure aluminum is separated and poured into the mold with alloying elements to create the desired casting shapes. The aluminum casting process can be done in many methods such as sand casting, die casting, or investment casting.

Comparison of Aluminum casting methods: https://vietnamcastiron.com/aluminum-casting-process/

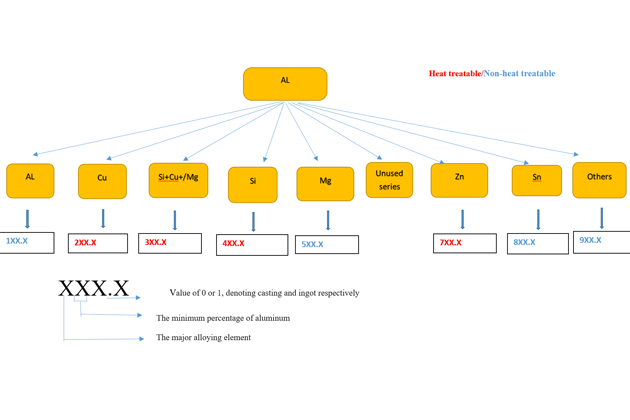

Cast aluminum alloys include 9 groups. According to the Aluminum Association (AA) designation, it is divided into two groups, similar to wrought aluminum alloys.

(Please note that British Standard and German Standard DIN have different designations).

- 2, 3, 4, 7: Non-heat-treatable cast aluminum alloys group; and

- 1, 5, 8, 9: Heat-treatable cast aluminum alloys group.

Groups are classified according to specific alloying element composition as shown below.

For example:

Aluminum alloy 356.0: The first digit (3) indicates that it is of Si plus Cu and/or Mg series; 56 corresponds to a minimum of 99.56% aluminum, and the .0 indicates that it is a final shape casting and not an ingot.

Table of Properties of Cast aluminum alloy series

| Alloy series | Corrosion Resistance | Strength | Machining | Weldability | Applications |

| 1XX.X | ☑ | ☑ | rotors | ||

| 2XX.X | ☑ | automotive cylinder heads, exhaust system parts, aircraft engine parts. | |||

| 3XX.X | ☑ | ☑ | ☑ | automotive cylinder blocks/heads, car wheels, compressor/pump parts, aircraft fittings. | |

| 4XX.X | ☑ | ☑ | ☑ | pump casings, cookware, and bridge railing support casings | |

| 5XX.X | ☑ | ☑ | sand casted parts | ||

| 6XX.X | – | – | – | – | unused |

| 7XX.X | ☑ | ☑ | |||

| 8XX.X | ☑ | ☑ | bearing applications | ||

| 9XX.X | others |

Designation System of Heat treatable and Non-Heat treatable aluminum alloy groups

Wrought aluminum alloy and cast aluminum alloy use the same Designation System for the non-heat-treatable aluminum alloy group and the heat-treatable aluminum alloy group. As follows:

Non-heat-treatable aluminum alloy

With aluminum alloy groups belonging to the Non-heat-treatable group, their strength is initially determined by the alloying element. The strength can then be increased (but decreased ductility) due to cold-working and strain-hardening processes such as rolling, forging, or pulling, etc.

After this state, the aluminum will have the final symbol “F” (as-fabricated). However, these alloys are eventually tempered to a constant temperature to ensure the mechanical does not change over time called temper stabilizing). These alloys have the following symbol with the letter “O” (annealed).

Non-heat-treated aluminum is commonly symbolized as: XXXX-Hxx

In which:

The letter “H” follows with the meaning that the aluminum has been “strain hardening” during the fabrication process.

The first digit after the H indicates a basic operation:

- H1 – Strain Hardened Only.

- H2 – Strain Hardened and Partially Annealed.

- H3 – Strain Hardened and Stabilized.

- H4 – Strain Hardened and Lacquered or Painted.

The second digit after the H indicates the degree of strain hardening:

- Hx2: Strain Hardened ¼

- Hx4: Strain Hardened ½

- Hx6: Strain Hardened ¾

- Hx8: Fully Strain Hardened

- Hx9: Extra Strain Hardened

Heat-treatable aluminum alloy

For the heat-treatable aluminum alloy group, durability is created by the alloying of the alloy elements with pure aluminum. The alloying elements can dissolve independently or combine together in a solid solution with aluminum as the temperature increases.

However, this aluminum alloy group is very sensitive to temperature, which if kept at high temperatures for a long time, will result in a significant decrease in strength.

Heat-treated aluminum is commonly symbolized as: XXXX-Txxx

In which:

The letter “T” follows with the meaning of Thermally Treated

The first digit after the letter “T” has the following meaning:

- T1: Aluminum is aged naturally (at room temperature) after cooling rapidly from high temperature due to the shaping process.

- T2: Cold worked after cooling from an elevated temperature shaping process and natural aging.

- T3: Heat-treated aluminum, cold worked and naturally aged.

- T4: Heat-treated aluminum and natural aging.

- T5: Aluminum is artificially aged after cooling from high temperature due to the shaping process.

- T6: Aluminum is heat-treated then artificially aged.

- T7: Aluminum is heat-treated and stabilized (overaged).

- T8: Heat-treated aluminum, cold worked, and artificial aging.

- T9: Heat-treated aluminum, artificial aging then cold worked

- T10: The aluminum is heat-treated, then cold worked, and artificially aged.

The second and third digits, after the letter “T”, if any, have the meaning of clarifying the specific thermomechanical treatment method.

Things to Consider when Choose Types of Aluminum for Casting Applications

You will find above that aluminum comes in a range of types and classifications. It may make you get lost and confused about how to choose the proper types of aluminum for your casting uses.

Don’t worry, here we help you specify which things you need to consider as the priorities while choosing aluminum material for the castings.

There are 4 factors mostly effect on which types of aluminum should use including:

- Which casting process to be used?

- How is the casting design?

- What are the required properties?

- What is an affordable cost?

Each of these above concerns involve special requirements on the types of aluminum used.

Let break it down!

- Casting Process: to consider criteria of fluidity, resistance to hot tearing, and solidification range.

- Casting Design: to consider criteria of solidification range, resistance to hot tearing, fluidity, and die soldering (die-casting) to choose with types of aluminum.

- Required Properties: to consider criteria of strength, ductility, heat treatability, hardness, corrosion resistance, surface treatments, dimensional stability, and thermal stability to choose with types of aluminum.

- Economic Consideration: to consider criteria of machinability, weld-ability, ingot and melting costs, and heat treatment to choose with types of aluminum.

Specify Types of Aluminum for Different Casting Applications

You got the tips to choose aluminum types on hand.

Here we go with some suggestions for specific casting applications.

Rotor Casting Parts

Most aluminum rotor castings are fabricated from a pure aluminum alloy that belongs to the 1XX.X cast aluminum alloy series, particularly 100.0 (99.0% Al); 150.0 (99.5% Al), and 170.0 (99.7% Al).

The reason for this strict requirement is to minimize variations of electric performance relating to conductivity and reduce casting defects such as micro shrinkage or crack on after the casting process.

100.0 Aluminum alloy has a higher amount of iron and other impurities, hence it improves the casting performance. As the result, the higher the iron content is, the less shrinkage and cracks are likely to be created. Therefore, Alloy 100.0 is recommended to cast rotor parts that have dimensions larger than125 mm (5 in.).

Same answer to explain that why Alloy 150.0 is preferable than Alloy 170.0.

Regarding rotor casting parts that require high resistivity, the higher alloys are used to process by die casting. Commonly types include Alloys 443.2 and A380.2. These types of aluminum alloys can increase rotor conductivities from 25 to 35% IACS.

Piston Casting Parts

Aluminum automotive pistons are mostly manufactured by permanent mold casting process due to its flexible and economic advantage.

Alloy 332.0-T5 is widely applied to cast pistons for passenger cars thanks to its good mechanical and physical properties (involve low thermal expansion).

Pistons for heavy-duty engines require high thermal conductivity and superior properties at elevated temperatures. Hence, common alloys used are 336.0-T551 (A132-T551), 332.0-T5 (F132-T5), 242-T571 (142-T571).

Premium-Quality Casting Applications

The premium quality casting parts have super high casting requirements on dimension accuracy and finish, mechanical properties, soundness, grain structure.

Alloys use for these premium quality casting uses can name A201.0, A206.0, 224.0, 249.0, 354.0, A356.0 (D356.0), A357.0 (D357.0) and 358.0.

The criteria to specify these alloys are:

(1) controlled impurities tightly and;

(2) optimum concentrations of hardening elements.

All of these alloys have excellent yield strength, tensile strength, and especially elongation that hence they can be choose to produce premium casting parts.

Standard General-Purpose Casting Parts

Generally, aluminum alloyed with Silicon series are mostly used to cast commercial aluminum casting parts because of excellent casting performance.

Alloys 443.0, 444.0, 413.0, and A413.0

Specifically, Alloys 443.0, 444.0, 413.0, and A413.0 additional provide superior corrosion resistance, excellent weld-ability, and low specific gravity. The detailed applications are listed below:

- Alloy 443.0: Applied to manufacture casting parts that require good ductility, resistance to corrosion, and pressure tightness more importantly than high strength.

- Alloys 444 and A444 for Permanent mold casting process: Application requires good impact resistance and high ductility.

- Alloy 413.0 and A413.0: Application in die casting which requires high fluidity to cast letter on the surface finish or high required surface smooth.

Alloys 213.0, 308.0, 319.0, and 333.0

Silicon plus Copper alloy series including 213.0, 308.0, 319.0, and 333.0 offer good casting performance, moderately high strength, and good machinability.

T5 temper can be added to some of these alloys to improve hardness and machinability.

Alloy 356.0

Alloy 356.0 (7 Si, 0.3 Mg) offers great casting ability and resistance to corrosion, hence widely applied in sand casting and permanent mold casting.

Additionally, 356.0 has good endurance makes it an affordable choice for complex castings that require materials with lightweight, excellent pressure, and good mechanical properties.

Typically, these aluminum alloys are used to manufacture: Furniture; Aircraft parts; Pump housings: Propellers: High-speed blowers: Automotive transmission cases: Water-cooled cylinder blocks; Engine controls; Nuclear energy installations, etc.

Alloy 380.0

Alluminum alloy 380.0 by far is the most widely applied material used in die casting process.

This alloy features very good casting-ability, good mechanical properties, less impurities and fair corrosion resistance.

Aluminum alloy 380.0 and A380.0 is commonly used for application of these flowing sections:

- Electronic and communications equipment

- Automotive components

- Engine brackets

- Air brake castings

- Transmission and gear cases

- Appliances

- Lawnmower housings

- Furniture components

- Hand and power tools

Conclusion

To sum up, we have discussed a detailed classification of different types of aluminum, their properties, and guide to choose an aluminum type for casting applications through the above content.

Please keep in mind that, selecting the proper types of aluminum for the casting parts is a very crucial process at the beginning that determines the casting part quality.

Hence, it is important to discuss with your customer toward the casting requirement for the material selection process.

Self-introduced, VIC is one of the leading aluminum casting foundries located in Vietnam and supplier of aluminum casting applications to the world need. As the OEM custom aluminum supplier, we manufacture cast aluminum products according to customer’s drawings and requirements.

Our casting products diversify, ranging from outdoor furniture, kitchen accessories, automotive parts, piston, bearing, to super high precise casting pieces.

If you are in need, don’t hesitate to contact us to place a discussion. Also, check our casting blog to get more updates relating to aluminum casting, foundry manufacturing weekly.

Reference

ASM Handbook. Volume 2B. Properties and Selection of Aluminum Alloys. Kevin Anderson, John Weritz, and J. Gilbert Kaufman, editors,DOI 10.31399/asm.hb.v02b.a0006575 .

ASM Handbook. Volume 2. Properties and Selection: Nonferrous Alloys and Special-Purpose Materials ASM Handbook Committee. p 123-151. DOI: 10.1361/asmhba0001061.