Here we list down and discuss 6 different types of casting processing commonly applied in metalworking foundries. Check here to specify the different types of casting process, pros & cons, and applications of each casting technique.

Casting is a metalworking process in the foundry that used to manufacture casting parts severing a range of industries, from mechanical engineering, automotive components, aerospace parts to everyday household products.

The casting processing works on melting metal, pouring into the molds, and waiting for solidification. The collected roughcasting either can be put in use directly or has to go through the further machining steps.

Metal casting is a highly flexible process and can fabricate complex-shaped parts regardless of the metal hardness, but only on the melting temperature of the metal. It can be said that any metal that can be melted can be cast.

There are different techniques to process the metalworking and each foundry invests and specializes in certain types of casting processing. In this article, we introduce the 6 different types of casting process commonly used in metal foundries. You will seek out the answer to how casting parts are processed by different types of metal casting methods and the pros & cons of each technology.

1. Green sand casting

What is green sand casting?

The green sand technique has such a long tradition in the casting industry but is still widely used today due to its effectiveness. The green sand casting is among the different types of casting that most traditional and preferable in the casting foundry.

In this casting processing, the sand mold is mass production. Each sand mold is used once and being broken to collect the roughcasting.

Different from the resin sand casting, green sand features wet-content. The term “green” not about its color, but moisture texture in the sand. It and has the ability to bond naturally mostly due to clay agents.

Green sand mold composition

To make a green sand mold, the metal foundry combines these following components:

- Sand: Silica sand (SiO2), Chromite sand (FeCr2O4), or Zircon sand (ZrSiO4) (about 75 to 85%)

- Bentonite Clay: (5 to 11%)

- Water (2-4%)

- Others (3-5%)

The green sand casting process

The green sand casting are processed by following these steps

- Step 1: Mixing the sand according to a ratio. It is very important that determines the bonding of the sand mixture. Each metal foundry follows the above ratio but they will have a secret mixing formula by adding other agents.

- Step 2: Loading sand into the mold maker and press the pattern to create the mold cavity. Today foundry uses a cope and drag device to make the sand mold.

- Step 3: Removing the pattern, a mold cavity that has a similar shape to the intent casting is created.

- Step 4: Applying a coating layer to the mold surface to increase the surface gloss and heat resistance.

- Step 5: Pouring the molten metal into the mold cavity and cooling. Collect the roughcasting and go further machining steps (if needed).

- Step 6: Repeating these steps to make enough mold for mass production.

Green sand casting characteristics

Advantage:

- It is economical and inexpensive production, particularly in low volume run

- Do not require very high tech investment in the factory facility

- Apply for medium and high volume casting order

- Allow any alloys to be poured into the mold (both ferrous and non-ferrous materials). Plus can use for almost pattern and design

- The sand can be reused after the casting is collected. It saves input material cost for the foundry.

Limitations

- Limit in casting size. It can make castings in a range of 1 to 500 pounds weight. For the larger, it should be considered other casting methods.

- Not preferable to cast intricate casting details

- Large tolerance that would need more machining treatments

- Create concerns on casting defects such as blowhole, porosity, etc. but can control by foundry’s technical tips.

Green sand casting applications

Green sand casting is very popular with a range of applications. In America, 42% of casting parts are made by the green sand process while no-bake casting, in comparison, takes 40% (the second popular casting method).

You can find the green sand casting parts, from outdoor decoration pieces such as lamp post, bench, litter bin; engineering details, automotive parts, aerospace, pump housing to marine buoy weight, etc.

Read more about green sand casting here.

2. Furan resin sand casting

What is furan resin sand casting?

Other common different types of casting process in metal foundries are furan resin sand casting. Unlike the green sand that provides natural bonding, the furan resin sand casting relies on some catalysts and binders to bonding the sand. In this casting method, the sand, furan resin, and Catalystsare mix together and the sand mixture is self-harden by the chemical reaction.

The roughcasting collected features good smooth surface finish and high precision.

Furan resin sand mold composition

In the furan resin sand casting, the mold is made by this following formula:

- Sand: Silica sand (SiO2) (40-60%)

- Furan resin: 0.7-1.3% depending on the casting mass. It is required less or without nitrogen accordingly to casting requirements and casting parts structure.

Furan resin play the important role in this casting method. It is a polymer compound with 75% Furfurylalcohol + 11% Formaldehyde + 9% Ure + 5% Water. The ratio of Formaldehyde and Urea affects the solidification time and the strength of the resin mixture, while Furfurylalcohol (FA) affects the heat resistant properties of the mixture.

- Catalyst: solidification agent and annexing agents (30-50%)

The furan resin sand casting process

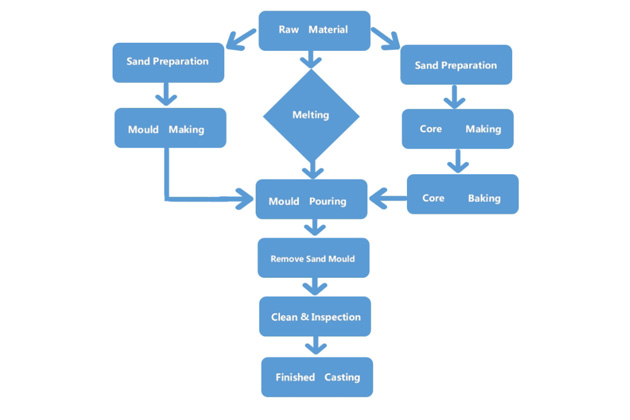

The furan resin sand casting processes are explained by the following chart:

Furan resin sand casting characteristics

Advantage

- Tight tolerance and high precision

- It provides a great smooth surface casting finish in comparing to other casting methods

- Minimize the casting defects such as sand holes, air holes, and shrinkage

- Flexible in casting size. Furan resin sand casting can make large pieces range from a dozen kilogram to several tons of weight

Limitation

- It is a more expensive method than other casting processes

- Strict requirement for raw material

- Creates environment concerns

Furan resin sand casting applications

With its excellent advantage, the furan resin sand casing is often preferred to cast intricate and detailed parts that require high precision and tight tolerance such as automotive parts, agricultural machinery details, aerospace parts, ship engines, etc.

Read more about furan resin sand casting here.

3. Lost foam casting

What is lost foam casting?

The lost foam casting is a kind of evaporative pattern process that similar to investment casting. Instead of wax, the pattern is made of foam in the lost foam method.

Unlike the sand casting, that pattern can be removed and reused to make other molds, lost foam pattern can be used once and is evaporated leading to form the casting parts.

Not as popular as sand casting, but the lost foam casting is one of the different types of casting process that remains pretty awesome features that suits to mass production of small and medium detail casting parts.

The lost foam casting process

The lost foam casting process follows these steps:

- Step 1: pattern making. The lost foam pattern can be made by cutting machines or by polystyrene beads injection molding method. The pattern can be a competed pattern (simple design) or a few sections then being glued together to form a replica of intent casting.

- Step 2: insulation paint coating to enhance the durability of the mold surface and protect from erosion and broken

- Step 3: the foam pattern is placed into a flask surrounding the unbound sand and being compacted.

- Step 4: pouring the molten metal, evaporating the foam pattern, and forming the roughcasting

- Step 5: cleaning the remaining sand and further machining if needed.

Lost foam casting characteristics

Advantage

- Flexible design

- Cast complex shape that unthinkable in other casting processes

- High precision and tight tolerance

- No core defects, no mold shift, excellent smooth surface finish

- Reduce the processing time

- Reduce production and investment cost

Limitations

- It is more expensive than other methods

- It will be very costly for set up or small orders

Lost foam casting applications

The lost foam casting does not limit to any design and type of alloy. It is often choosing to cast complex casting parts that other methods unable to work. For example automotive detail parts, high precision machinery elements, intricate core products…

Read more about Lost foam casting here.

4. Investment casting

What is investment casting?

Investment casting or lost wax casting is an advanced casting method used to cast complicated and thin-wall shapes. This process is similar to the lost foam casting. Instead of the foam pattern, the disposable wax pattern is formed by the injection method then coated with several layers of refractory material.

By melting the wax pattern, a mold cavity is created and ready for the metal liquid being poured into. Note that the pattern is used only once and that each casting needs a pattern.

This method has the characteristics of casting details with high accuracy, so it is often preferred to cast products for the machine manufacturing industry, especially the production of small details, high precision, without machining or cannot be machined.

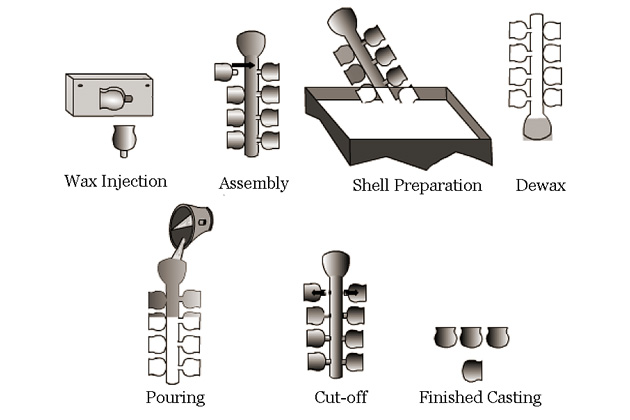

The investment casting process

- Step 1: Making the master pattern and mold

- Step 2: Inject the wax into the mold to make wax patterns.

- Step 3: Assembling pattern sections

- Step 4: Shell making

- Step 5: De-waxing by heat

- Step 6: Pouring the molten metal

- Step 7: Shattering

- Step 8: Cutting off

- Step 9: Finished casting parts

Investment casting characteristics

Advantage

Investment casting is a modern casting approach with many advantages.

- Compared with sand casting, lost wax casting can make better complex details, thin walls, high surface quality, and significantly reduce machining works. Many finished casting parts can be used immediately.

- It can make products weighing from a few grams to a ton.

- Can cast hard-to-melt alloys such as stainless steel, thin steel

- The casting surface is high precise and gloss

- The casting is less likely to crack or warp

Limitations

- High labor intensity

- Long production cycle

- Mold manufacturing costs are high

Investment casting applications

Complex castings, or in mass production to fabricate gears; bicycle trunks; moto disc; spare parts in blasting machine … Casting with weight from 0.02 ÷ 100kg; thickness to 0.3mm and hole diameter to 2mm.

5. Die casting

What is die casting?

Die casting is the molding material method under high pressure and applied to cast non-ferrous metals and alloys.

It is used in casting parts for bulk orders because the advantage of this casting method is its high productivity and simplified process thanks to the application of a fully automated line. The roughcasting collected has tight tolerance, high precision, and a nice gloss surface finish.

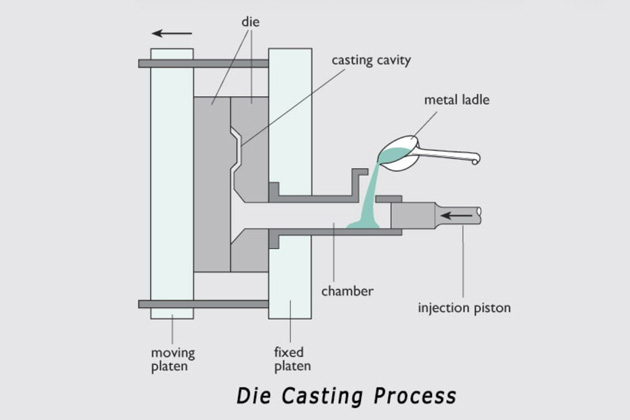

The die casting process

- Step 1: Melting the metal into fluid

- Step 2: Pouring the molten metal into the chamber

- Step 3: High-pressure piston injection system pushes the fluid into the mold

- Step 4: Wait until the casting has solidified, then remove the core

- Step 5: The latch will eject the object out

- Step 5: Remove the scrap materials and continue the next segment

The entire casting process of the die casting method requires the use of high-pressure pistons and tight presses to ensure the durability of the casting. With the automatic line process, the quality of the casting depends on many factors such as molten metal composition, machinery system, casting pressure, etc.

The die casting characteristics

Advantage

- Tight tolerance and high precision

- Able to cast thin-wall casting even 1mm

- High gloss casting surface

- High consistency on dimension and uniform design

- Reduce machining work

- High volume production efficiency and suit for bulk up order

- Completely automatic lines that save the labor cost

Limitations

- Expensive tooling cost

- Requires advance machinery investment

- Limit in molding design

Die casting applications

Die casting is often used in the casting of small parts, bulk orders such as pistons, crankshafts, gearboxes, etc. It can produce the casting that often weighing up to 5kg, but there is also a casting case for parts weighing up to 50kg but the price is very high.

The alloys used in die casting need to be uniform, have good dilute properties when melted and the composition is stable to not adhere to the mold, and have a plastic strength when heated at high temperatures. Copper, aluminum, and stainless steel are often preferred in this casting technology.

In die casting, aluminum alloys are used the most compared to all other alloys. In the US alone, aluminum die casting is worth up to $ 2.5 billion annually. Particularly, aluminum die casting accounts for twice as much as all other methods combined.

6. Permanent mold casting

What is permanent mold casting?

Permanent mold casting, also known as metal mold casting is a casting process in which a mold is made of metal like die casting. It is used to produce a large quantity of castings by using a single reusable mold. The mold can be reused many times hence the so-called permanent molding method.

Permanent mold casting is suitable for larger castings than die casting, about 10kg, of course, it can be higher, 20kg even 50kg, and the cost will be higher.

The permanent mold casting process

The permanent mold casting process is simply included these steps:

- Step 1: pouring molten metal into the mold

- Step 2: allowing for cooling and solidifies

- Step 3: opening the mold and collecting the casting;

- Step 4: then continuing these above processes to make as much casting as required.

Notably, the mold in this process is made from a high-temperature metallic material such as cast iron to be able to bear the continuous heating and cooling involves while taking big volume.

Permanent mold casting characteristics

Advantage

- High precise and tight tolerance casting result

- Nice surface finish with less casting defect as sand casting does

- The casting is a high strength, toughness, and ductility

- The durability of the mold is high.

- Due to saving mold making time, high productivity reduces production costs.

Limitations

- It is difficult to cast objects that are too complex, with large walls and weight

- Mold manufacturing costs are high.

- There is a need for a mechanism to push the casting out of the mold, so they sometimes form a dent in the casting.

Permanent mold casting applications

This permanent casting mold is most commonly used to cast aluminum, magnesium, copper alloys, and gray cast iron because of its low melting point. Suitable for mass production with simple and small or medium-sized castings such as pistons, gear billets, kitchen utensils, details in machine tools, aircraft wheels, pump parts, etc., that is not heavier than 25kg. For objects with a complex internal shape, it is recommended to use a sand core.

Summary

The above content has listed down and analyzed the 6 different types of casting process commonly used in the metal foundries manufacturers. Overall, each of these casting technique maintains both strengths and limitations. Depending on the casting requirements and project demand, the foundries will consider the casting process that suits the application.

As one of the leading casting companies and wholesale to the world market, VIC is the sand casting foundry with three main casting techniques included green sand casting, furan resin casting, and lost foam casting. With these three different types of casting, we are able to manufacture any casting parts, from the small, medium, large size to simple, intricate shape design. Contact VIC foundry for an OEM casting part project via email [email protected].