Aluminum sand casting surface finish is not as smooth as other casting methods. However, the foundry can improve the roughness of aluminum casting and increase its look by strictly controlling the choice of sand, mold coating components, mold compaction technique, pouring temperature, and additional processes.

There is always a list of criteria that you can look at to adjust the quality of a casting. In this article, we are going to discuss one of the important factors that most of the time concerning by the customers – surface finish.

For many buyers, a smooth surface finish of the casting parts more than the bonus visually appearance. This first testing round by naked eyes can be a sign to show off that the foundry provides high-quality casting parts.

From the technical view, the surface finish results in the performance of the casting products. A poor quality casting surface with defects such as porosity, cracks can lower the strength of the products, and lead to an increase in the eventual cost for cleaning, finishing, and machining.

The surface finish varies from the casting process. In the content frame of this post, we only focus on the discussion of the surface finish of cast aluminum in sand casting.

You will find at our post a deep analysis of the factors determining the aluminum sand casting surface finish and suggestions to obtain a “look-good” appearance.

- Does sand casting produce a fine aluminum surface finish?

- Which factors determine the aluminum sand casting surface finish?

- Mold material/ Choice of sand

- Types of molding sand

- Composition of molding sand

- 5 Properties must consider when choosing molding sand

- Molding Compaction Methods

- Mold Coating

- Pouring molten metal process

- Machining and Finishing

- Conclusion

Does sand casting produce a fine aluminum surface finish?

Although there are many methods to fabricate metal casting parts, sand casting is still one of the most preferable processes applied in foundries. Statistically, more than 70% of casting parts worldwide are made from sand casting with its presence in a range of industries, from outdoor furniture, transportation, automotive, energy, marine to aerospace.

Briefly, sand casting is the molding method in which sand is the main material to build the mold for the casting. The sand casting process can be divided into 2 main types based on the different ways of sand bonding that is green sand casting and furan sand casting.

Explained the popularity of sand casting, it is an economic casting method and flexible in casting part sizes (allow to manufacture from a few pounds to several tons). With respect to simple casting products, foundry prefers to use green sand casting to minimize the cost. At the same time, furan resin sand is suitable to produce more complex details and its manufacturing cost is higher.

Sand casting is a cost-saving method overall, however, they remain a huge consideration on its surface finish. The aluminum sand casting surface finish is often poorer than other casting methods such as die-casting, shell mold casting, or permanent mold casting.

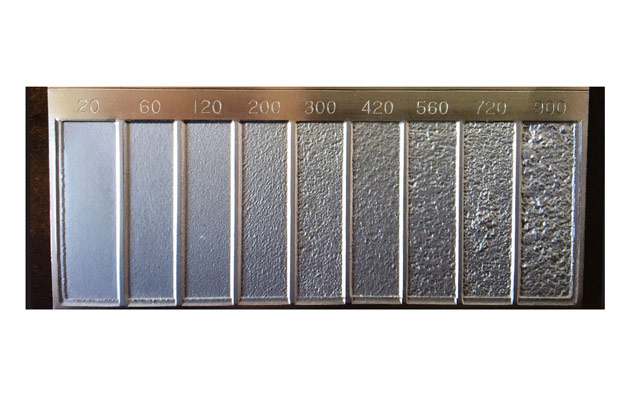

You can refer to the typical aluminum sand casting surface finish and other processes measured by the American Foundry Society Comparator counted by RMS (Root Mean Square) unit in Table 1 below.

Table 1: The aluminum surface finish in different casting processes

| Aluminum Casting Methods | Surface smoothness in RMS |

| Green sand casting | 250-900 |

| Furan sand casting | 150-600 |

| Vacuum casting | 150-600 |

| Lost foam casting | 125-175 |

| Die casting | 90-200 |

| Shell molding casting | 75-150 |

| Investment casting | 50-125 |

Accordingly, the typical sand casting surface finish aluminum ranges from 250-900 RMS in the case of green sand casting (poorest among the casting methods) and a better surface finish in case of furan resin sand casting (150-600 RMS).

Generally, in comparison to other aluminum casting methods, the surface finish of aluminum casting in sand casting is among the poorest. This is the reason why most aluminum sand casting products required additional processing such as surface treatment, machining, finishing to be completed.

Which factors determine the aluminum sand casting surface finish?

As mentioned above the sand casting surface finish of aluminum can range from 150 RMS (acceptable and less machining required) to 900 RMS (required a lot of additional processes). In fact, the foundry can reach the minimize roughness by well controlling the factors affecting the aluminum sand casting surface finish.

Here we list down and specify the elements that have a huge influence on the surface finish of the aluminum sand casting that you must always keep in mind.

Mold material/ Choice of sand

Different mold material will determine the surface finish level of a casting.

Sand is the main material accounting for a large majority of the mold in aluminum sand casting. So that the surface finish of casting depends greatly on the sand types and their quality. Any breakdown in sand mold can result in the roughness casting surface finish.

Hence, choosing sand material for the molding requires knowledgeable considerations on the qualified sand types.

Types of molding sand

Classified according to the composition

Based on composition, molding sand can be divided mainly into 2 types: natural or synthetic.

Natural molding sands include a sufficient amount of binder, whereas synthetic molding sands required adding artificial binders and additives to bond sand grains. Naturally, bonding sand is often known as green sand with good moisture content, while furan resin sand is mostly used as synthetic molding sand.

Green sand saves cost for the manufacturer as well as the final price to the customer, however, with respect to the smoothness of casting surface finish, green sand doesn’t bring a good surface finish (Table 1).

On the other hand, the cost for resin sand is higher, but it delivers a better aluminum surface finish. This type of synthetic sand is usually applied to fabricate high surface required applications such as automotive parts.

Classified according to their uses

Molding sand also can be classified based on their uses, including backing sand, core sand, dry sand, facing sand, etc.

Table 3: Characteristics of types of molding sand for different uses

| Types of molding sand | What it used for? | Features |

| Backing sand/ floor sand | Back up the facing sand and fill the molding sand flask | Reused sand |

| Core sand | Making cores | High silica sand mixed with oil binders |

| Dry sand | Using for larger castings | It is green sand that is dried and baked after the molding and core making. It obtains more strength, rigidity, and thermal stability. |

| Facing sand | Contact with the pattern and molten metal accounting 15% whole amount of molding sand. | A mixture of silica sand and clay. Require high refractoriness |

| Parting sand | Keep the green sand not to stick to the pattern, and separate the cope and drag | Clean clay-free silica sand |

Composition of molding sand

Table 2: The constituent of molding sand

| Compositions | Features |

| Silica sand | The main composition of molding sand that have sufficient refractoriness to impart stability, strength, and permeability of molding and core sand. |

| Binder | Inorganic substance: Kaolinite, Ball Clay, Fire Clay, Limonite, Fuller’s earth, and Bentonite Organic substance: dextrin, molasses, cereal binders, linseed oil, and resins like phenol-formaldehyde, urea-formaldehyde, etc. Mostly used binder is bentonite. |

| Moisture | The moisture content of the molding sand ranges from 2 to 8%. This amount of water is held rigidly by the clay and is mainly responsible for developing the strength in the sand. |

| Additives | To improve the special properties of molding sand. Common additives are coal dust, cornflour, dextrin, sea-coal, pitch, wood flour, silica flour, etc. |

5 Properties must consider when choosing molding sand

Sand fine level

In the bonded sand processes, the finer the sand grains are, the smoother the aluminum casting surface finish is.

When the molten aluminum flows into the cavity, the larger sand grains can create peaks and valleys that cause roughness on the surface. On the other hand, the fine sand grain can sit tightly to produce a smooth casting surface finish.

However smaller sand grains also result in a less permeable mold and gas trapping that is the cause of porosity and other gas casting defects in the final casting.

Refractoriness

Refractoriness is the sand’s ability to bear the heat or temperature of the molten aluminum poured without breakdown. If the refractoriness of sand is not sufficient, it can cause the sand to be melt and fuse to the casting.

With respect to aluminum casting, molding sand is required to withstand a heat of 650°C (1202°F).

Permeability

Permeability refers to how well the sand can vent and how well the gases pass through the sand. This sand ability allows exhausting the gasses such as nitrogen, steam, hydrogen, and carbon dioxide that generated as the aluminum fluid is poured.

If the molding sand is less permeable, these gasses can be trapped resulting in gas defects such as gas holes, blow holes in the final aluminum casting parts.

Cohesiveness / Bond

Cohesiveness is the sand bonding ability to maintain the casting shape as the pattern is withdrawn without any breakdown.

This property is very crucial because if the sand is not bonding enough, casting defects can create as the mold cavity is not fulfilled.

Collapsibility

As the casting solidifies, the sand is required to be easily collapsed to allow the free contraction of the aluminum. If the sand has poor collapsibility, the contraction of aluminum is hindered by the mold, hence, resulting in defects such as hot tears and cracking. This property is especially needed in cores.

Normally, additive is added to the molding mixture to improve the sand collapsibility.

Molding Compaction Methods

Compaction is the process in which the sand is rammed and pressed into the mold. The sand mold required to be tightly and correctly rammed to ensure that all the mold edges are fully filled and unable to be broke during the casting process.

This step can be carried out in different methods and the different ways of molding compactions deliver different smoothness levels in aluminum sand casting surface finish.

Table 4: The smoothness measurement of different molding compaction methods

| Compaction methods | Surface finish measurement |

| Hand ramming | 1 |

| Blowing | 3 |

| Jolt-squeeze method | 4 |

| Automatic molding machines | 5 |

Note: Each compaction method is given a certain point in the measurement table. The smoothness level increases from 1 to 5. Respectively 1 refer to poor smoothness, and 5 is superior smoothness.

Mold Coating

Mold coating is a layer designed to withstand the high temperature as molten aluminum flows into the mold cavity and a barrier between the hot aluminum fluid and mold & core surface. Mold coating is also known as a protective coating, refractory coatings, washes, etc.

The effects of mold coating on aluminum sand casting surface finish

The mold coatings are suspensions of a high-temperature mineral or refractory in a liquid form. After being coated on the mold or core surface, the liquid evaporates and a refractory layer sticks on the sand surface.

This layer acts as a protective layer to reduce or eliminate phenomena such as metal penetration, burn on, erosion of sand by molten aluminum, scraps, and thus improve the aluminum casting surface finish and lower the cleaning costs.

The better refractory layer on the mold coating, the smoother the aluminum sand casting surface finish you will see.

However, please well noted that the benefits of mold coating on improving the sand casting surface finish obtain only if the coating layer is chosen properly, applied, and dried correctly. Improper coating types or incorrect preparation can lead to poor surface finish and even coating defects such as scabs, blows, gas holes, inclusions, etc. in aluminum sand casting.

Component of mold coating

Mold coating is a mixture of:

- Refractory Mineral

- Carrier / Reducer

- Binder

- Suspending Agent

- Special Additives

Refractory Mineral

This is the most important element in the mold coating. Refractory typically accounts for 90-95% in the coating layers, while other components only represent 10-15%.

The refractory mineral plays a vital role in determining the resistance of the coating barrier to the molten aluminum, the effects of coating on the aluminum casting properties and surface finish.

Refractories are often blended to improve the aluminum sand casting surface finish.

Choosing the refractory mineral for aluminum mold coating requires foundry to consider these following concerns:

- Able to withstand a temperature above 650°C (1202°F).

- Thermal Conductivity

- Thermal Expansion and Contraction

- Cost

- Toxicity

- Permeability

Common used refractory minerals in foundry are graphite, coke, charcoal, silica and mica.

Carrier / Reducer

Carrier, reducer, or solvent, vehicle often used interchangeably to refer to a liquid phase of the coating composition used to dilute the coating mixture.

The function of the carrier, as its name, to carry the refractory particles to the mold and core surface. After the coating is coated, the fluid of the carrier will evaporate and leave the refractory layer sticking on the mold and core surface.

There are several criteria foundry has to consider when choosing the carrier including:

- Compatibility of the carrier with the binder and refractory

- Coating method (spray, dip, brush, flow coat, swab)

- Drying method and available tools

- Cost of carrier and working labor

- Drying speed requirement

- Toxicity

Our recommend carriers to increase the surface finish as well as meet almost all the above requirements are Water and Isopropyl Alcohol. Additionally, you can also consider Methanol and Naphtha.

Binder

The binder component is to bond the refractory particles together as well as sticker refractory particles to the sand. Common binders commonly used by foundry includes acrylics, starches, and wood derived resins.

The binder chosen must ensure the balance of film hardness, flexibility, adhesion to sand, and loss upon ignition. The proper binder creates a good dry film harness that allows the dry coating to bear the handling, affords to accommodate sand expansion, and prevents the formation of porosity.

Suspending Agent

The suspending agent works to keep the suspension of the refractory particles and prevent the coating to be hard settling and maintain the viscosity of the coating as it is applied to the mold and core surface. Moreover, the suspending agents also affect how easy to remix the coating (in case it required) and how to apply the coating (dipped, sprayed, brushed, swabbed).

Some of common suspending agents are polymers, gums and clays.

Special Additives

Special additives such as biocides, dispersants, leveling agents, defoamers, wetting agents, etc. are added to the mold coating to modify and increase other properties and performance of the casting as required.

Pouring molten metal process

Although the preparation of sand mold is the most vital factor determining the quality of aluminum sand casting surface finish it also required the foundry caster to take other technical processes into account to obtain the smooth castings.

Aside from the melting process, the foundry must control and calculate the sufficient aluminum pouring temperature in the effort of smoother the surface finish.

Radiant heat from the aluminum fluid can cause to lower the quality of the mold surface resulting in the poor surface finish of the aluminum casting.

Also, the turbulence caused by improper pouring heat can lead to casting defects in the aluminum sand casting such as flaws in the surface finish of the cast aluminum products.

You can refer to the pouring conditions of cast aluminum to increase the surface of your foundry aluminum casting parts here.

Machining and Finishing

Unlike other aluminum casting methods, sand casting surface finish remains more roughness that requires more additional processes to smoother its look.

Normally, the aluminum roughcasting in sand casting often goes through the machining and surface treatment steps.

It is a good alternative choice in case you don’t want to change other advanced casting methods to keep the low cost. Thus, you can discuss with your clients about machining and finishing solutions.

It is depended on your foundry facilities and equipment. But we recommend sand casting foundries should invest in shot blasting machines or CNC machines (turning, grinding) to improve the appearance of your castings.

Conclusion

It is true that you should not adjust a book by its cover. But it is truly a bonus when the cover is as good as its story inside. We believe that a good casting surface finish delivers its functions even better.

At our aluminum foundry, we always put ourselves in the customer’s shoes to deliver beyond their expectation. For all of our aluminum casting products, it must not only look good but also perform well. From metallurgy research, the choice of mold material, compaction, coating types, casting temperature conditions to machining, we all strictly control and calculate to maximize the perfection of the aluminum casting products as well as minimize the cost for the clients.

Hopefully, you will find helpful information through our sharing. Don’t hesitate to leave a comment to share your thought and contribution to our topic. If you are seeking more technical advice on metal casting, check our blog weekly to get updates.

All the best!

Good day. I am Valerie from Moldova, I really liked your video on aluminum casting. I am doing high pressure aluminum casting. And by high pressure zinc casting. I think to start casting in a chuck, but there are questions. What kind of paint is used to paint the cockle inside? and where to buy a magician? Thank.