Besides the design, lamp post paint color blows an elegant, eye-catching, luxurious look to the illuminating fixture which complements anywhere the lamppost belongs to. Additionally, the coating also works to enhance the durability of the lighting fixture. Together with us to explore which lighting post paint type commonly used and some of their advantage & limitations.

Outdoor lighting is growing popularly as not only an illuminating fixture but also an addition to the architectural curb appeal.

With different application and installation, the lamp post comes in a variety of color and painting types.

This post will introduce popular color of outdoor lighting post and common paint used for lighting post manufacturing.

Let’s together with us to explore what kind of paint should you use to paint a lamp post and how to paint lamp post!

Popular lamp post paint color

Besides the illuminating function, the lighting post is widely applied for exterior landscape decoration for example garden, park, sidewalk, historic place, street…

At present, there is a lot of paint color for lighting post commercially. At Vietnam Cast Iron, dark grey, black, green, and gold are the most preferable lamp post paint color.

These lighting pole colors blow an elegant, eye-catching, luxurious look to the illuminating fixture which complements anywhere the lamppost belongs to.

Common lamp post paint types

Some may think that there are only a few paint types, there is no difference between them, and doesn’t really take the paint type into account when buying the lighting post.

The fact is that numerous types of lighting post paint are available. Each type performs different benefits and limitations. Especially, the paint type also puts its weight on the durability and appearance of the lamppost.

Below lists some of the typical paint types for lighting fixtures using in the manufacturing process. Let’s check how the foundry paints the lamp post and which paint is the best.

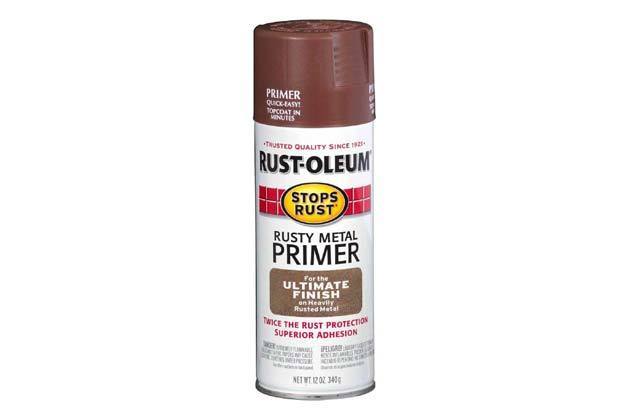

Primer paint

The primer paint is not compulsory within the lamppost manufacturing process. However, adding this painting layer will bring great effect to the lighting fixture look as well as quality.

The primer paint has different features than the topcoat. It is a foundation layer before applying the topcoat paint.

The prime paint works as a lamp post first painting layer to:

- Surface protection from corrosion/rust: Aluminum and cast iron are the two common materials used to manufacture outdoor lighting posts. While aluminum is easy to be corroded, cast iron can be rust after long use. Hence, the prime coating helps to prevent and limit the above concerns.

- Aesthetics enhance: The primer layer also acts as a stable base layer, enhancing the adhesion between the top coating and the material surface. Therefore, the topcoat painting will perform the best color quality and uniformity, ensuring the aesthetics of the lamp post visual.

How to paint Lamp post using primer paint?

In order for the primer paint to adhere firmly to the lamp pole surface, it is necessary to:

- Clean the surface before painting. In the foundry, after the roughcasting is collected, it is gone through the sandblasting and again eliminated remaining dirt, marks, or stains.

- After that, choose the suitable tools for the lampost parts such as a paintbrush, roller, or paint gun to paint evenly on the surface.

- Wait for the paint to dry.

- After having a stable primed layer, continuing to coat the lighting post surface will provide the most optimal effect for the lamp post look. Because of its good adhesion ability on the painted surface, the coating is like a coat to protect the painted lamp posts.

Three common topcoat painting types including the normal color paint, epoxy paint, and powder paint are introduced below by Vietnam Cast Iron.

Normal color paint

Most of outdoor lamp post is applied at least the color paint layer. Color paint performs some advantages such as:

- Good adhesion on the surface.

- The paint film is durable, has high wash-ability, and dries quickly.

- The color paint has a diverse and impressive color palette, so it will serve the maximum needs of customers.

- Cheap price.

Not only has a protective effect, but the color paint coating also adds a decorative effect. With a variety of selections, the color paint will help your lamp post fixture stand out, and highlight your architectural appeal.

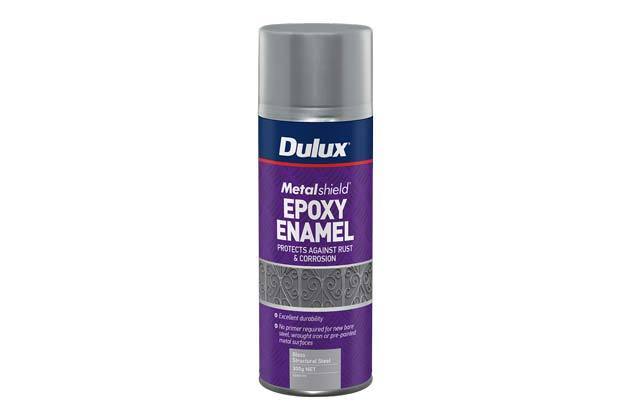

Epoxy Paint

Another common used paint type for exterior lamppost is the epoxy paint.

Featuring being placed outdoor, the lamp post often has to withstand the different weather conditions and external factors leading to easy to be rust/corrosion. Excellent in the anti-corrosion ability, epoxy paint is widely used for outdoor lamp poles production.

Epoxy paint protects the internal structure against oxidative corrosion from the surrounding environment factors and increases the life span of the structure to be protected.

It provide a good protection and decoration layer to galvanized steel, stainless steel, cast iron, and aluminum surfaces.

Furthermore, the epoxy paint has a range of color, performs the perfect lamppost surface, waterproof, oil-proof and easy to clean.

Advantageous by anti-corrosion and good surface visuals, but the cost of epoxy paint is higher than normal color paint, and the painting process also requires skillful and experienced labor.

Powder Paint

Have you ever seen the lampposts with glossy paint, hard to scratch, and especially very smooth? These lighting posts are coated with powder paint.

Powder paint is a popular coating method in Western countries and dates back to the 1960s in North America. Powder coating is essentially a dry finishing method, opposite to conventional painting using water or solvents.

This method performs many advantages:

- Economic: For the conventional coating, the adhesion is only about 30-40%, meanwhile, the adhesion of the powder coating is 60-70%. Additionally, the remaining paint can be reclaimed and reused.

- Safety: Powder paint does not contain harmful solvents and organic compounds.

- Durability: The powder coating is resistant to abrasion, scratches, and other wear caused by thermal bonding during use. In addition, the powder coating retains the color very well despite long-term exposure to moisture, sunlight.

- Environment-friendly: According to a few studies, compounds in conventional paint are capable of damaging the ozone layer and require a lot of costs for industrial treatment. On the other hand, powder coating is made from plastic powder, so it does not seriously affect the environment.

Although there are many great advantages over traditional coating method, but powder coating is not without drawbacks.

The biggest disadvantage of this method is the initial investment cost. Equipment procurement will be very expensive because the system is very complex including spray guns and compressed air power supplies.

In addition, the system also requires an oven and a high voltage power supply for the spray gun.

Due to the high investment cost, the price per lamppost with powder coating is also higher than other painting methods.

VIC – One of leading Lamp post manufacturer

Lamppost base before painting

Lamppost base after paiting

Vietnam Cast Iron is the lighting post manufacturer and exporter. We are able to provide both available in-stock products and OEM lampposts according to customer’s requirements.

Our product selection is various from individual lamppost parts such as cast iron lighting base, aluminum base & pole, lighting arm to completed lighting post fixture.

Let’s see Lamp posts that are manufactured in VIC: https://vietnamcastiron.com/lamp-post-component/

For our outdoor lighting post, we provide different painting requests of customers. Either primer paint, epoxy paint, normal color paint, or powder paint, we are able to meet all your needs.

Check our website to see our product quality and manufacturing capacity. Also, contact us to get a quote and meet our lighting post expert for your specific project.

Contact information

- Company: Vietnam Cast Iron Co.Ltd

- Address: Lai Xuan, Thuy Nguyen District, Hai Phong city, Vietnam

- Email: [email protected]