Lamp post component is manufactured by the metal casting process. Producing a qualified lighting post to adapt both quality and safety standards requires very complex processes including designing, casting, machining, and quality testing.

Lighting post keeps an important role in illuminating and enhancing the architectural appeal for the both public and private landscape.

Lamp post is quite familiar with all of us. It may catch your eyes everywhere, from your front yard, along the road to your office, to beside your institution entry. But have you ever wonder how the lamp post parts are manufactured?

To produce a qualified outdoor lighting post that adapts both quality and safety standards, it requires very complex processes including designing, casting, machining, and quality testing.

In this article, VIC’s lighting post expert will introduce the basic steps to manufacture the lamp post casting parts and the international standards for lighting post. Grab this knowledge will help you easily choose suitable lighting posts as well as a supplier for your project.

Stay with us to explore and get more knowledge.

- Which parts included in a lamp post?

- Manufacturing Lamp post components step by step

- Step 1: Designing the drawing, specifications

- Step 2: Making the pattern

- Step 3: Making mold

- Step 4: Pouring molten metal

- Step 5: Sand blasting

- Step 6: Machining & Painting

- International Standard for lamp post

- Lamp post manufacturer and supplier

Which parts included in a lamp post?

Have you ever ask “What are Lamp post parts“?

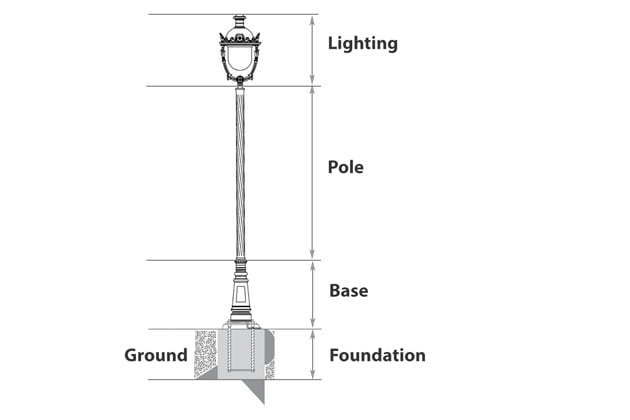

Commonly, a lamp post include three part which are foundation, body, and top.

1. Foundation

The invisible section of a lighting post is the foundation. This part is buried in the ground and works as a house basement to keep the whole post light stable over external factors.

2. Body

The lamppost body includes the pole and the base sections. The lamp base is often cast from cast iron material aiming at supporting and withstanding the weight of the upper parts.

The rod iron post is usually made of aluminum, cast iron, or stainless steel. The pole often taller twice to several times than the lighting post base depending on the typical lamppost models.

3. Top (Lighting)

The top part includes bulb, lighting arm, and ornaments. The design for this section comes in a variety of styles.The cast iron lamp is mounted on top with lighting cover.

The following introduces basic steps to cast outdoor lamp post parts. Let see how it works.

Manufacturing Lamp post components step by step

Step 1: Designing the drawing, specifications

The drawing and specifications can be designed either by the customer for OEM products or by the manufacturer for ODM service and on stock lamp posts.

Commonly, the customer will provide the lamp post drawing along with their requirements about casting technology, surface processing, and material standard to the foundry. The drawing can be either 2D or 3D.

Another case is customer work with the manufacturer about their design requirement and the manufacturer will be in charge of drawing.

The manufacturer will read the provided drawing, consider all of the requirements, and adjust accordingly to suitable with their production ability based on close discussions with the customer.

After the drawing and requirement have approved, the drawing will be sent to the manufacturing department.

Step 2: Making the pattern

The pattern making is the first and most significant in the casting process in general and in the lighting post part manufacturing particular.

A pattern is a replica of the final lighting post product which used to create mold cavity for molten metal pouring step.

Commonly, the foundry relies on the drawing to design the pattern for lamp post component including lamp pose base, post, and top.

The pattern for lamp post parts is often made from aluminum material and processed through CNC machine.

Step 3: Making mold

The pattern making for lighting post sections has to consider the removal step to guarantee the lamp post quality and cost effectiveness.

Depending on different lamp post models, the molding making technique will be considered.

Popular molding methods for casting lamp post component are green sand casting, lost foam casting, furan resin sand casting.

For the simple design and fewer details of the cast iron post, base, and lamp parts, the manufacturer will prefer the green sand casting process. This molding method is advantageous by low production cost, then save money for the buyer.

For the high detail and ornamental details of the lighting arm, lost foam casting or furan technology will be considered. These two methods are excellent in casting complicated shapes and performing smooth surface finishes.

Whatever the process is called, basically the molding step is implemented by putting the pattern into a flask containing sand, pressing, and forming the mold cavity.

Step 4: Pouring molten metal

Once the mold cavity is created, the molten metal pouring is processed. Depending on each lamp post casting part, different metals will be melted.

Cast iron is often used to cast lighting post base, whereas aluminum and aluminum alloy is applied to produce lamppost pole.

The molten process of the two materials is not similar.

The chemical composition of cast iron consists mainly of Iron (more than 95% by weight) and carbon & silicon. By adding different elements in the melting process, the foundry can create various types of cast iron such as gray cast iron, white cast iron, ductile iron, etc.

The melting point of cast iron is around 1150 to 1200 ° C, 300 ° C lower than that of pure iron. While, the melting point of aluminum is about 600 °C, lower than cast iron.

As soon as the molten metal is ready, it is poured into the mold cavity. Waiting for cool down, then the lamppost roughcasting is completed.

Step 5: Sand blasting

The roughcasting of the lamp post part will be collected and gone through the sandblasting for cleaning the remaining sand. This process can be done by either manual or automatic machines.

Step 6: Machining & Painting

Machining lamp post base

Painting lamp pole

In accordance with customer’s requirements, the lamp post roughcasting will continued to be machining and painting.

The intersection between lamp post components will be machining the surface to the pieces fit tightly together.

Additionally, the lamp post pole, base, and arm are often coated paint layers. The most commonly used paints are the color paint for the aesthetic; the powder paint & epoxy paint to maintain the smooth surface and prevent corrosion and rust.

Reference about painting: https://vietnamcastiron.com/lamp-post-paint/

International Standard for lamp post

There are international standards that include provisions on the lighting post design and manufacturing. The three most widely applied standards are the European EN 40 standard, ISO 8995-1:2002(E)/CIE S 008/E:2001, and CIE S 015/E:2005.

The lighting post design must ensure the safety of the user as well as the convenience of lighting, guarantee the luminous efficiency, help the light shine evenly and strongly, etc.

The material of the lamppost also must meet the prescribed measurement standards. They are required for rigidity, pressure & extreme weather resistance.

Details about Lamppost material: https://vietnamcastiron.com/lamp-post-material/

Lamp post manufacturer and supplier

VIC is a world-class lamp post manufacturer to the USA, Canada, UK, Belgium, Germany, France, Japan, the Middle East, etc. We specialize in casting OEM and ODM lamppost parts according to a variety of tastes. Check our products to see some of our lamp post models.

At Vietnam Cast Iron, we put ourselves in the customer shoes to understand their needs. We are towards to bring the real value to our partners so that for all of our lighting post products, we guarantee both the high quality and competitive price.

Cooperation with us will surely worth your money. Contact us to meet our expert to get advice and quote for your specific project.

- Company: Vietnam Cast Iron Co.Ltd

- Address: Lai Xuan, Thuy Nguyen District, Hai Phong city, Vietnam

- Email: [email protected]

Read more about ‘LIGHTING OF WORK PLACES’ STANDARD: http://cie.co.at/publications/lighting-work-places-part-1-indoor