Counterweight

Casting cast iron Counterweight is the core product of the VIC. We are able to produce OEM casting cast iron, ductile iron, and steel counterweights for various applications and mass. Our casting counterweight products are guarantee high quality and competitive prices, meeting international standards.

Counter weight is an integral object with a range of applications in constructional, agricultural, industrial areas.

At VIC, the cast iron counterweight is our primary product. We are able to produce OEM cast-metal counterweight for different purposes such as crane, forklift, kettlebell, marine buoy, elevator, etc.

Our counterweights are made from 3 main materials namely cast iron, ductile iron, and steel.

All of our casting weight products are manufactured meeting international standards, applying modern technologies, and maintaining competitive prices.

Check our cast iron counterweight casting product categories to see some counterweight casting we offer and our casting ability. Also, contact us for your own drawing and requirement.

List of our casting Counterweight products:

Showing all 13 results

Counterweight Definition

A concise definition provided by Vietnam Cast Iron will help you get first imagination about what does counterweight means as well as what does it do.

By meaning, a counterweight is an object helping to maintain the stability and balance of a mechanical system. Purposely, it plays the role to make lifting the load efficiently leading to save the energy and reduce pressure on the lifting machines.

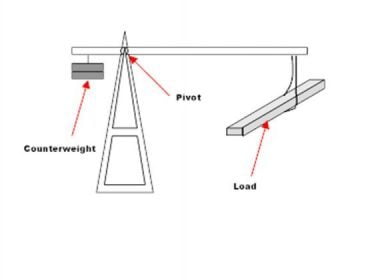

How does Counterweight works?

Counterweights help to counterbalance a load when doing lifting or lowering. In order to work efficiently, a counterweight of mass has to be suitable as needed and being placed at an optimum distance from the center support (tipping point as well-known). Simply, counterbalance mass is multiplied by the distance from the counterweight to the tipping point. In physics, this is called the moment.

Simply, counterbalance mass is multiplied by the distance from the counterweight to the tipping point. In physics, this is called the moment.

For the most efficient running, the moment of the counterbalance must be equal to the load moment.

This point is very important because it is to avoid overbalancing on either side. If the moment of one side is larger than the other, the smaller side will be collapsed as a result.

Applications of Counterweight

The counterweight has a range of applications in construction and machinery industries such as elevators (lifts), cranes, excavators, forklifts, tractors, etc.

Application in Trebuchet

Trebuchet or Trebucket is a type catapult. The very first counter weight usage was trebuchet in the medieval period.

At that time, Trebuchet was a siege engine used to throw projectiles (usually weight 50 to 100 kg) into enemy basements from a distance. It was the most popular and powerful weapon in the Middles Ages until the gunpowder invention.

The trebuchet is a huge structure, with 5 main elements namely counterweight, frame, beam, guide chute, and sling.

After the cast iron counterweight drops from a platform on the frame, gravity pulls the counterweight and pivots the beam.

Without the counterbalance, the beam could not complete the arc that allows the sling to accurately release the projectile.

Application in Elevator (Lift)

The cast iron counterweight is an essential part of elevator system design. Ideally, the weight of a counterbalance is equal to the weight of the lift car plus 40 to 50 % of its rated capacity.

Regarding its function, cast iron counterweight does counterbalance a load of lift carriage (lift car), save energy, and keep safe for the lifting system.

Normally, the motor needs so much force to move the car. However, when applying the counterweight system in the elevator, it is very much easier for the motor either up or down the car.

In addition, because the motor requires a lot of power to move the car, therefore, the counter weight system works to save the energy needed by the motor.

Consequently, less energy used leads to less energy consumption. Then the running cost and maintenance are reduced as a result.

Application in Crane (Tower crane)

Crane (or Tower cranes) are commonly used at major construction sites to raise loads up to 120 tons.

A tower crane consists of a central tower with two arms holding a fixed and a mobile counter weight. The operator moves the mobile counterweight to balance the load.

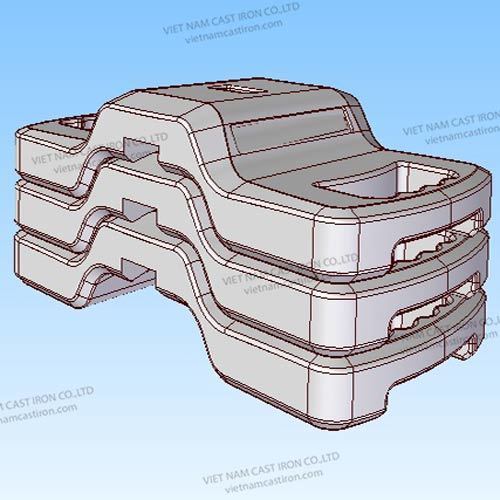

Application in Excavator

Excavator is a heavy construction machine often used to dig out foundations, trenches, and holes.

The heavy-duty design of excavators needs counterweights to counterbalance the excavated earth. Without it, the vehicle can tip over.

What are counterweights made of?

The counterweight material varies for different purposes. Manufacturers can use either full metal, full concrete, or a mix between concrete and metal to produce counterweight. Cast iron, ductile iron, and steel are commonly used metals.

For example, heavy-duty machines such as excavators and cranes often require both metal and concrete mixture for counterbalance. While forklift counterweights often use metals to maximize space utilization.

Advantage of Cast Metal Counterweight comparing to Concrete one?

Although concrete counterweights are cheaper than cast metal products, it is wiser to choose cast metal for the following reasons.

Regarding density, cast metal counterweights have three times more density than pure concrete on average.

This property enables to save the space and volume for cast metal counterweights in comparison with the concrete product. With the same weight, the concrete counterweight size is often bigger three times than cast metal one.

Concerning product cost, although the concrete material is cheaper than cast metal, on average the cost per product of concrete is also high. This is because to maintain the density, the concrete mixture needs to add more additional components such as limonite, hematite, magnetite, scrap, a metal bit. So the production cost increases many times.

With respect to durability, cast metal products are more superior to concrete products. Cast metal materials such as steel, cast iron, ductile iron are stronger and harder than concrete. Therefore the metal counterweights have better pressure assistance and longer durability than concrete products.

For all of these above reasons, cast iron counterweight, ductile counterweight, and steel counterweight are preferable in applications than concrete products.

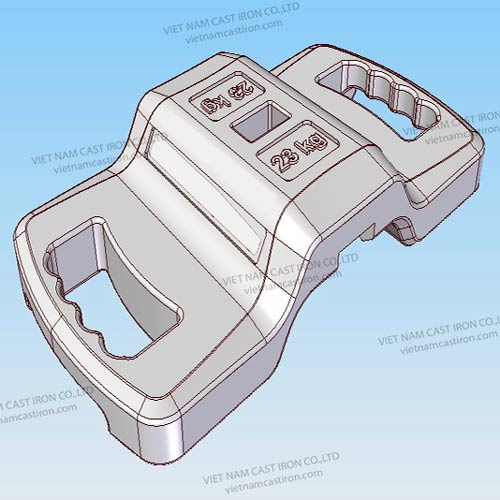

Counterweight Mass

Counterweight mass is various depending on its applications. A single counterbalance can weight from 1 kg to 50 tons.

Common sizes are 600 kg, 50 kg, 100 kg counterweights for heavy-duty machines, or small sizes such as 2 kg, 5 kg counterweights for other applications.

Which technology used for cast iron Counterweight?

Green sand casting is the most popular and commonly used to cast metal counter weight products.

In green sand casting, mold is formed by green sand. Unlike shell molding and no-bake casting which sand is bonded by using heats or chemical compounds, green sand for metal casting is unique by bonding sand naturally, mostly due to the presence of clay agents.

Green sand casting method maintains some excellent advantages suitable for cast counterweight such as affordable and reasonable cost, versatility with production, flexibility in the choice of molds and patterns, and friendly with the environment.

How to choose counterweight suitable for your purposes?

So far, you already get basic knowledge relating to counter weight from its functions to applications. You may wonder how much mass counterweight does I need or which material should use for a counterweight. Don’t worry, our technical expert will guide you clearly.

Before decide to buy a counterweight, it is important to figure out which type of counterbalance do you need. For different purposes, counter weight comes various in sizes and materials.

For example, counterweights for the marine industry require corrosive resistance due to the salty of water. So concerning counterweights for marine buoys, boats, cast iron material is commonly used. On the contrary, steel material is not popular because of its corrosive property.

With respect to agricultural machines, ductile iron and steel are advantageous. Due to mechanical and movable properties, these heavy-duty machines require toughness counterweights. Therefore, cast iron is not recommended in this application because of its brittle property.

Regarding counter weight mass, it is also vary depending on each application.

Vietnam Cast Iron Counterweight Product

VIC is one of the leading manufacturers of cast iron counterweight products. The counter weight is also our core product. Therefore, out of our 7 factories, we especially spent one facility for metal counterweight production.

At VIC, we are able to produce any weight of counterbalance for various applications. From counter weights for building constructions, agricultural machines, to marine industries, we have all the cast metal solutions to meet your demands.

To secure reliable and safe performance, VIC combines the best raw material selection with high-quality manufacturing processes for our product manufacturing.

VIC is confident to guarantee our cast iron counterweight products are strongest, most durable, best quality, and price maintains very competitively.

An order with Vietnam Cast Iron will save you money upfront and long term. Call us today to find out how we can make your project exceptional.

Contact information:

- Company: Vietnam Cast Iron Co.Ltd

- Address: Lai Xuan, Thuy Nguyen District, Hai Phong city, Vietnam

- Email: [email protected]

VIC-CW01

VIC-CW01

VIC-CW02

VIC-CW02

VIC-CW03

VIC-CW03 VIC-CW04

VIC-CW04 VIC-CW05

VIC-CW05 VIC-CW06

VIC-CW06

VIC-CW07

VIC-CW07

VIC-CW08

VIC-CW08

VIC-CW09

VIC-CW09

VIC-CW10

VIC-CW10

VIC-CW11

VIC-CW11

VIC-CW12

VIC-CW12

VIC-CW13

VIC-CW13